The "Extended" Collection for No4T Sniper - CES (Complete Equipment Schedule). and CESSI (Complete Equipment Schedule Supplementary Issue) - Going Beyond the Chest...

- artiozen

- Sep 16, 2022

- 10 min read

Updated: May 6, 2025

Content Credit to Bruce Bairnsfather with permission (written and photo content/ use) - denoted as "BB" where used.

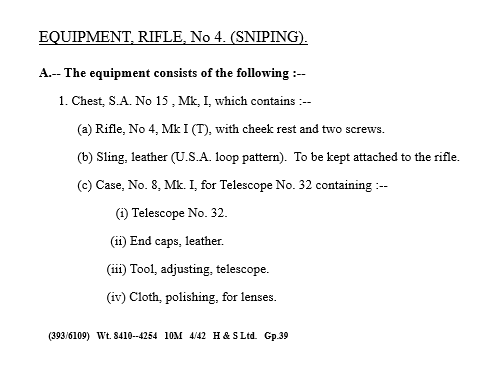

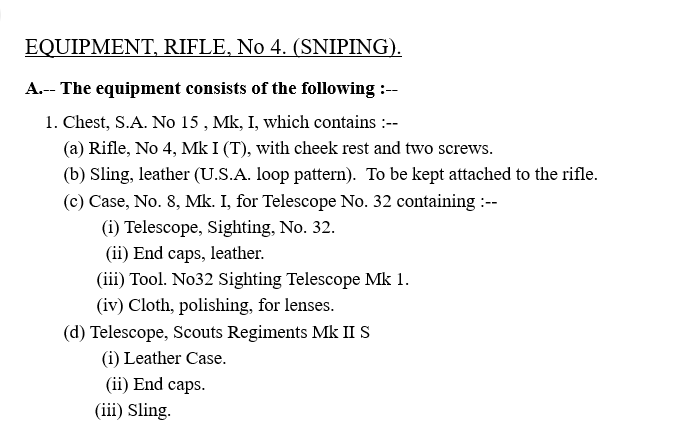

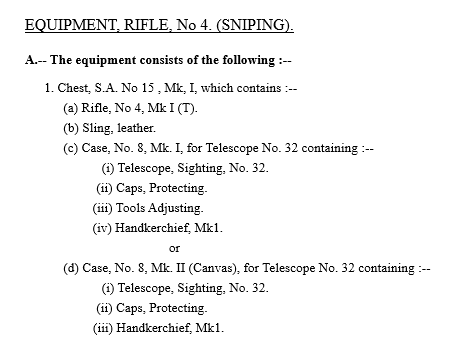

Above: The SANO 15 Chest Lid Labels show the No4T CES changes over the war years, May 1942, Oct 1944 and Aug 1945 respectively.

Possible CES

Lens Cleaning

Scout Regiment Telescope MkII and Mk2

Rifle Cleaning Kits

9mm / British 303

Scrim Veil (Camouflaged)

1907 Sling (Leather)

No8 Scope Tin / Case

Scope Adjustment Tool (Mk1 and Mk2 Scopes Only)

Possible CESSI

Binoculars

Map Case and Contents

Prismatic Compass (Liquid)

General Service Time Piece (GSTP / Watch)

Denison Smock

Rifle Valise

Other Supplies / Equipment

Tabby - the worlds first active night vision set

BREN Spare Parts tin & optional contents

Depending on the year of service that your sniper rifle and associated kit represents, there are a wide range of equipment and accessories that can represent that snapshot of the gears 50+ years of service in many nations around the world. Often these pieces of optional kit / accessories came and went, or made a return depending on supply, demand and the doctrines developed for the tasks in hand. Some of these pieces may seem obscure but the devout Lee Enfield Sniper Collector may want to "have them all".

No8 Scope Tin / Case (with Carry Strap)

Link to dedicated Blog article on No8 scope tin varieties and details:

Lens Cleaning:

While gasmasks were issued to all ranks and theatres (up to and including D-Day June 3rd 1944), the British Commonwealth issued a variety of gasmasks and supporting equipment. One of these issued items was cotton waste - which was designated for cleaning the eye pieces of the gasmask - dry and in a manner to remove dust / dirt. The issued sniper equipment of this time did not designate a cleaning material, so it is thought that the gasmask supply of cotton waste was carried over to clean all manner of lenses. I will check the early training manuals to see what is said for scope lens cleaning and report back. As the gasmask became obsolete - in late 1944 the need for official means to clean the No32 scope lenses was recognized and each SANO chest kit label was altered to include a "Handkerchief mk1" - yes! the humble khahki hanky! These were already a stores item and readily available - so in they went! Several good example photos and specimens show this folded square in the left hand part of the scope carry tin, trapped behind the incumbent scope. Now with war surplus and the passing of time, these handkerchiefs have become used, lost and rare. Added to the No4T "Sniper" fervor - an original hanky from stores has become the thing to acquire!

1907 Sling (US Pattern - Leather)

Purchased in the First World War along with the P14 rifles and other war materials, these slings were applied by the British to several weapons applications over thee next 80 years. Stored in bulk in Weedon Depot (Northamptonshire) until needed - they were specified as part of the P14 Sniper kit, which was later designated No3T sniper rifle and this is the model that entereWW2 with the BEF.

Naturally when the No4T was devised and released the 1907 Sling, Leather (US) went along with it (as did the cheek piece which was originally developed for the scoped P14 / No3 rifles). Genuine UK issued slings are WW1 dated and have been observed with various years and makers marks - I'm sure Weedon and its replacement depots would be getting low on them by now.

Binoculars

The Binoculars included with a No4 T C.E.S, were the standard Service 6 X 30 No 2 Mk ll at the inception of the No4 T in 1941. Although as they were unit issued it may well be that whatever 6 X 30 binoculars were available were issued to the Sniper teams. It was a requirement that the binoculars had ranging graticules in the right side ocular.

The Bino Prism No. 2 Mk II, was first introduced in 1909, it was the British Army’s designation for a 6X30 prismatic binocular with graticules. The marking at the top of the right prism plate reads, "Graticules 1/2° apart and 1/4°, 1/2°and 1° high" referencing the graduations on the graticule in the right ocular.

The Bino Prism No. 2 Mk III was introduced about 1942 to replace the No. 2 Mk II. The Mk III had improved water-proofing, and had desiccator vents in the objective end cover plates sealed with round headed screws, which were often painted red, to distinguish them.

Photos and text - BB

The No. 2 Mk ll & III were manufactured by Kershaw, Taylor Hobson. Henry Hughes, and Cooke, Troughton and Simms.

The standard issue post WW2 was

The Number 2 MK lll , which later bore the NATO designation V6/1240-99-963-3737. They continued in service through to the 1970s and beyond, it was to be found in the CES of the L42A1.

Substitute 6 X 30 binoculars of North American production were frequently found on issue to Commonwealth troops and by and large they were superior in performance to the British manufacture.

The Canadian binoculars were manufactured by R.E.L (Research Enterprise ltd), these would have been standard issue for Canadian troops. These featured a unique body shape due to the prism formats used which also means they fill the case snugly.

Photo and text - BB

The U.S binoculars were supplied under Lend Lease and were manufactured by a number of suppliers. These are often the M6 or M13 models. Although the North American binoculars were slightly larger due a similar prism format to the Canadian made examples, they would fit in the P'37 binoculars case but not the P'44.

Scout Regiment Telescope Mk1 to Mk2

British military telescopes seem to march on through time. As the second world war loomed there was a recognized need for a fairly compact medium magnification telescope for most uses - signals, artillery and command. It was to be 3 draw with near infinite focus by length adjustment, 20 magnification with a sun shade and a lens filter for the optical lens (can be flicked into line of sight with a thumb tab), made of brass which was blued to subdue it when it was exposed, sheathed in leather and to be held in a leather carry case with shoulder strap.

Photos and text - BB

First introduced as the Mk l in April 1924, further development saw the introduction of the Vulcanised Rubber covering in February 1939. The provision of webbing straps instead of leather was also permitted at this time. In August of the same year, it was authorised that Telescopes submitted for repair, would be recovered in Vulcanised Rubber. The Mark of these repaired telescopes would then be advanced to Mk I*.

The Mk II telescope was manufactured from this time also (1939). The final wartime model with the tinted shade fitted was the Mk IIs. Both of these Marks can be found in either leather or Vulcanised Rubber.

This was designated as the Scout Regiment Telescope mkII and pressed into service in the late 30's with contracts going to 4 major suppliers for up to 80,ooo examples over the course of the next few (war) years. As the No4T was pressed into service, this telescope was added to its basic CES for the sniper (note that snipers were trained in all roles and skills and worked in teams of 2 to 5 - there was no "spotter" designation yet). It was the application to the No4T CES that made the scope famous, bought about its regard as the 'sniper telescope" and increased its collectible popularity. Post war production group can be discerned as they adopt the 1946 standard for Arabic numbered mark revisions - so mk2 instead of mkII.

Post war there were rebuilt for cold war stores and could be updated with better blackening and repairs to the leather. In the 1980s new green plastic carry cases were procured and deployed. Using the scope itself was an acquired art form for handling, steadying and focusing - time was dedicated for this in sniper schools. At some point the Scout Reg Telescope was eliminated from the Cold war CES for the No4T - its pocket in the transport chest being simplified or redacted also.

Here we see an early production scope (in the first 2000 serial number range) finished in all leather and showing some signs of use and wear - with 20% of the blued brass finish remaining - and no signs of rebuild. Still fully serviceable with working sun shade and eye filter.

Here are other makers marks observed and captured to date The HCR made example shows the Arabic numerals mk2 - and is post 1946 production. The two BC made examples demonstrate an early production low serial (in leather) and late war serial (in textured thermoplastic).

Map Case and Contents

Prismatic Compass (Liquid)

One of these was on issue to a Sniper team and would easily fit on a P37 webbing belt, when inside carried in it's webbing padded case, or inside the pockets of the Denison smock, loose.

The liquid filled Mk lll prismatic compass was of heavy brass construction, it was a development of the earlier compasses of WW1.

It specifications were.

- Weight: 285 gr

- Compass card: mother-of-pearl

- Divisions: 360 deg., clockwise.

Photo and text - BB

Our example is a 1940 dated Mklll manufactured by T.G. Co Ltd of London. This company name disappeared as soon as WW2 finished. It is thought that this name was probably used to keep secret the manufacturer's real identity.

The letter 'B' in the serial number most likely indicates that this compass was in reality produced by F. BARKER, a well known compass manufacturer. It is carried in its P37 padded webbing case manufactured by Finnigans Ltd in 1941.

Even when superseded by cases issued with P44 and P58 webbing equipment these useful cases remained in production into the 1960s by the Mills Equipment Co.

GSTP (Watch)

The Sniper role was principally one of observation, reconnaissance (and signals), so timebound reports and activity coordination was paramount. The British Army contracted personal timepieces to be issued to most ranks as special accountable issue from the Boer war on. Many moderate and premium watch makers were awarded contracts over the century of service and were typically commonly marked and executed - only digging deeper into the mechanisms can the variation and pedigree be determined.

WW1 did see the use of wrist watches as issue and private purchase (for officers), the GSTP though remained a pocket watch (without chain) all the way through WW2. This allowed the timepiece to be incorporated into personal kit with chords or thongs of leather and carried and worn as practical - just be careful as it as to be returned to store and inspected - damage docked from pay if lost or damaged.

Rifle Cleaning Kits

We now look at the cleaning kits for the No4 T which were to be found with rifles issued towards the end of WW2 and for the remainder of their service. Thereafter with the L42A1.

When the No4 rifle was accepted into service in 1941, it was provided with the long serving pull through with brass weight and the Mk lV brass oiler which had been in service since 1906. These were both stored in the buttstock of the rifle.

The first official cleaning kits in a tin, were issued for the STEN in 1945. Its parts and application though worked with many British and Commonwealth small arms. Although not specified in any of the wartime CES it is often included in period photos of kit displays and would take root in the post war training manuals and go through a few iterations to change with the times.

9mm / British 303 wartime and cold war tin. A stepped lid tin with a U bracket spotwelded into the base to make 3 flexible compartments with 2 partitions, with a windowed bracket spot welded into the lid to hold 2 wire gauze patches and form a clip for the cleaning brush.

Typical contents - 12 section length of 2 X 4 flannel patch, an oil bottle - typical war time black thermoset plastic, single pull-through (steel or brass weighted), an action brush - plastic bristles in a wood, aluminium or steel handle and two wire gauze patches.

These were for use with the pull through for removing Rust or fouling from the barrel. Their use however could only be permitted by an officer as repeated use would cause damage.

The use of brass, steel and plastic items continued in parallel as they remained in stock.

By the late 1950s with the arrival of the 7.62 L1A1 S.L.R , the tin was adapted to the new rifle. Gone was the retaining clip in the lid with its pieces of wire gauze which were no longer sanctioned.

The tin now contained in addition a Multi tool for the S.L.R , the pull through weight was by now steel and incorporated an angled cut end, which could be used to remove fouling. The oil bottle was plastic. The ubiquitous '4 x'2 remained. In this is form the cleaning kit remained in use for the length of service of the No4 T the L42A1 and the L1A1 SLR. At the conclusion a plastic box was on issue.

There are two versions of the 7.62 kit observed - the flat lid typically made by XCD in 1972 and stepped lid typically made HB&S in 1973. The former features a phosphor bronze brush that can be attached to the multi tool - this version is the typically observed version for the L42 chest.

Photo and partial text - BB

A Beech wood chamber cleaning stick was added into the C.E.S and chest lid of the L42A1 sniper rifle.

Denison Smock & Veils

Rifle Valise

BREN spares part tin

Longer patrols needed more cleaning and maintenance contingencies - a smaller tin with high risk parts - extractor with springs and screw from the armourers (attached to the division), a screw driver to change this if needed (will check if the butt plate trap spring will do this with or without modification). Sniper teams would try and select ammunition lots, but even in WW2 the variation of size and performance may lead to fouled, strained or broken extractors.

Photo - BB

Also from the BREN kit - a 303 case extractor. Upon ejecting a separated case (back half) the front of the case is captive in the forward chamber - simply load the ruptured case extractor, it passes through and retains the forward part of the ruptured case and then is ejected like a spent round - clean as soon as you can - probability is you can continue firing safely if engaged. Drill Purpose round for checking the chamber and new extractor after field expedient repair. Spare hand grenade pin - the multipurpose tool of the battlefield!

Tabby - the worlds first active night vision set

The worlds first Infrared Night Vision Device - held as Top Secret throughout the war and used on essential missions only (two are documented to be used by the pathfinder units that marked the beach extremities for the shipping lanes of the D-Day invasion). Held in a robust custom fit case with a double groove in the body to avoid the operating button. These were a sealed unit and were to be destroyed by fire and buried when the batteries failed or in the face of capture. To be put in the hands of the highly trained observer on missions of paramount importance.

Comments